Introduction to Machine Vision

In today’s rapidly evolving technological landscape, machine vision has emerged as a crucial enabler of automation and efficiency across various industries. This technology synthesizes imaging systems, computer algorithms, and artificial intelligence to allow machines to interpret visual data, a function traditionally reserved for human operators. Consequently, machines equipped with vision systems can perform complex tasks such as quality inspection, measurement, and identification, all while maintaining speed and consistency that surpass human capabilities.

What is Machine Vision?

Machine vision is a subset of computer vision that focuses on enabling machines to process visual information in real-time. It typically involves the use of cameras, electronic sensors, and sophisticated software algorithms to capture and analyze images for a myriad of applications. At its core, machine vision allows machines to “see” the environment, make decisions based on visual input, and act accordingly. This may involve detecting defects in products, directing robotic arms to assemble components, or even guiding autonomous vehicles.

Historical Development of Machine Vision Technology

The concept of machine vision was born from the need to automate repetitive tasks that require visual perception. In the early days of manufacturing, machine vision systems were rudimentary, relying heavily on analog methods and basic image processing techniques. The first significant advancements occurred in the 1960s and 1970s when early digital imaging technologies began to emerge. These developments paved the way for more sophisticated image processing algorithms in the 1980s and 1990s, as computational power significantly increased.

By the early 2000s, machine vision had transformed into a vital component within various industries, from automotive manufacturing to pharmaceuticals. Innovations such as 3D imaging, artificial intelligence, and deep learning have further enhanced the capabilities of machine vision systems, allowing for real-time analysis and decision-making previously thought impossible.

Importance of Machine Vision in Industry

Machine vision systems are integral to modern manufacturing and other industries for several reasons:

- Quality Assurance: Machine vision allows for high-speed inspection of products for defects, ensuring that only quality products reach consumers.

- Increased Efficiency: By automating inspection and measurement tasks, machine vision reduces the time spent on quality control and minimizes human error.

- Enhanced Data Collection: Machine vision systems can gather data on product quality trends, enabling manufacturers to make informed decisions and improve processes continuously.

- Cost Reduction: Automating visual checks and measurements reduces labor costs and improves resource allocation.

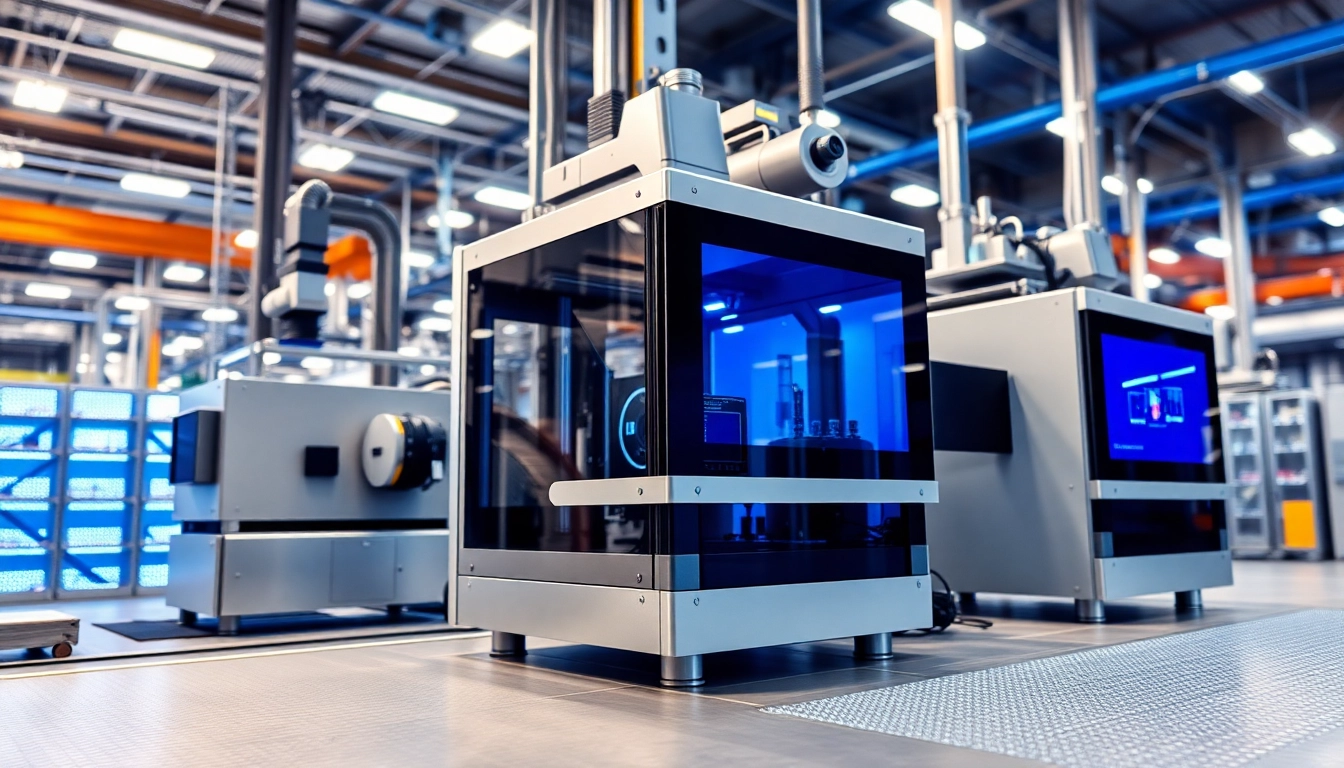

Key Components of Machine Vision Systems

A machine vision system comprises several critical components, each playing a vital role in the overall functionality and performance of the system.

Cameras and Sensors in Machine Vision

Cameras are the eyes of machine vision systems. They capture visual data which is then processed to extract meaningful insights. Various types of cameras are used in different applications:

- 2D Cameras: Used for simple applications such as barcode scanning and defect detection.

- 3D Cameras: Provide depth information, crucial for tasks like part assembly and complex inspections.

- Infrared Cameras: Used in applications that require low-light operation or thermal analysis.

- High-Speed Cameras: Essential for capturing fast-moving objects in real-time inspections.

Processing Hardware and Software Algorithms

The processing unit in a machine vision system analyzes the images captured by the camera. This can be achieved through dedicated hardware (such as Field-Programmable Gate Arrays or Graphics Processing Units) or standard computers running specialized software. The choice of hardware is crucial as different applications might require varied processing power.

Equally vital is the software that operates the system. Machine vision software utilizes algorithms for image processing, pattern recognition, and decision-making. Popular techniques include:

- Edge Detection: Identifies object boundaries and shapes.

- Image Segmentation: Divides an image into meaningful sections for detailed analysis.

- Machine Learning: Adapts and improves systems by learning from data inputs.

Lighting Techniques for Effective Imaging

Lighting is a crucial aspect of machine vision as it significantly affects image quality and system performance. Proper illumination enhances contrast and helps to reveal details critical for accurate analysis. Different lighting techniques include:

- Direct Lighting: Good for detecting surface defects.

- Diffuse Lighting: Reduces shadows and highlights surface imperfections.

- Backlighting: Ideal for silhouetting features against a bright background.

- Structured Lighting: Projects patterns onto the object to enable depth perception and measurements.

Applications of Machine Vision

Machine vision has a wide range of applications across various sectors, fundamentally changing the way industries operate. Below are some significant use cases:

Quality Control and Inspection Processes

In manufacturing, machine vision systems are primarily utilized for quality control. These systems are capable of examining products at high speeds, identifying defects, and ensuring compliance with specifications. For example, in the automotive industry, machine vision can inspect vehicles for paint quality and assemble line accuracy. This not only accelerates the inspection process but also provides higher reliability than manual inspections.

Automation in Manufacturing Environments

Machine vision plays a pivotal role in the automation of manufacturing processes. It is used for robotic guidance, where the system helps to locate and handle components accurately. For instance, in electronics manufacturing, machine vision systems ensure that components are placed correctly on circuit boards, thus minimizing errors in assembly. Furthermore, machine vision enhances the ability of robots to work collaboratively with human operators in shared spaces, improving overall productivity.

Machine Vision in Healthcare and Safety

The application of machine vision in healthcare is on the rise, where it is used for imaging processes such as microscopy, tumor detection, and surgical assistance. In pharmaceutical production, machine vision systems can perform checks on label accuracy and pill counts. Additionally, machine vision is instrumental in safety applications such as inspecting construction sites or monitoring the compliance of safety equipment in real-time.

Machine Vision vs Computer Vision

While often used interchangeably, machine vision and computer vision are distinct fields with different applications and methodologies. Understanding the differences is essential for professionals within the tech industry.

Defining the Differences and Overlaps

Machine vision is primarily concerned with manufacturing and industrial applications, focusing on automating inspection and measurement tasks. In contrast, computer vision encompasses a broader range of applications, including image analysis and understanding, facial recognition, and video surveillance.

The technologies often overlap; for instance, both fields utilize similar algorithms for image processing but apply them to different end goals.

Use Cases for Each Technology

Machine vision is the backbone for many industrial processes, as previously stated, focusing mainly on inspection and automation. Conversely, computer vision plays a vital role in areas such as:

- Self-driving Cars: Utilizing multiple sensors and cameras to analyze the surrounding environment.

- Healthcare: AI-assisted imaging applications for diagnosis and patient monitoring.

- Smart Agriculture: Analyzing crops via aerial imaging for precision farming.

Technological Advancements Impacting Both Fields

Recent advancements in artificial intelligence and machine learning are transforming both machine and computer vision. The ability to analyze vast amounts of data and learn from patterns is enhancing both fields significantly. This can be seen in the increased efficacy of inspection systems in manufacturing and more accurate image recognition algorithms in general computing applications.

Future Trends and Innovations in Machine Vision

The future of machine vision is exciting, with numerous trends shaping the landscape. Here are some anticipated developments:

Integration with Artificial Intelligence

The integration of AI into machine vision systems is set to revolutionize how machines interpret visual data. Early systems operated on predefined rules. The shift towards AI enables adaptive learning, allowing systems to improve performance over time based on feedback. Predictive analysis can further enhance quality control and manufacturing efficiency, making it possible for systems to foresee potential issues before they arise.

Emerging Technologies in Machine Vision

Emerging technologies such as augmented reality and enhanced imaging systems, including hyperspectral imaging, are making waves in machine vision. These advancements not only improve the accuracy of inspections but also expand the range of objects that can be analyzed. For instance, hyperspectral imaging can identify chemicals remotely and is particularly useful in agriculture and environmental monitoring.

Impact on Job Markets and Skills Development

The proliferation of machine vision will undoubtedly change workforce requirements. While some traditional jobs may become obsolete due to automation, new roles will emerge focused on managing and maintaining advanced vision systems. The demand for data scientists, engineers, and professionals skilled in AI and machine learning will rise, necessitating a shift in education and workforce training programs to adapt to this technological transformation.

In conclusion, machine vision stands at the forefront of technological innovation, unlocking new efficiencies, enhancing quality control processes, and paving the way for the future of automation across numerous industries. As technology continues to advance, its transformative power will only grow, leading to more remarkable advancements in the way we understand and interact with the world around us.

Leave a Reply