Understanding Steel Fabrication Services

In today’s industrial landscape, steel plays a fundamental role in construction and manufacturing. From architectural frameworks to machinery components, the need for quality steel fabrication services has increased dramatically. For businesses and individuals seeking these services, the phrase steel fabricators near me is often a starting point. But what does this truly encompass?

What Are Steel Fabricators Near Me?

Steel fabricators are specialized companies that manufacture steel products from raw materials by cutting, shaping, and assembling the steel into various forms and structures. When searching for “steel fabricators near me,” customers typically find local businesses capable of meting out high-quality fabrication services tailored to meeting specific project needs. These fabricators often serve a wide range of sectors, including construction, manufacturing, and energy, providing a pivotal resource for both small-scale and large-scale projects.

Common Services Offered

Steel fabricators offer a variety of services, some of which include:

- Metal Cutting: Utilizing saws, lasers, or plasma cutting to produce precise steel sections.

- Metal Welding: Joining two or more steel components via welding techniques such as MIG, TIG, and stick welding.

- Metal Bending: Curving or shaping steel plates to project specifications, often using presses or rollers.

- Assembly and Finishing: Assembling various steel parts and applying surface finishes, such as galvanizing or powder coating, for protection and aesthetics.

- Custom Design Work: Collaborating with clients to create bespoke steel products tailored to specific functionalities and designs.

Benefits of Local Fabrication Services

Working with local steel fabricators presents several advantages:

- Timeliness: Proximity allows for quicker turnaround times and delivery schedules.

- Communication: Improved communication due to reduced geographical distance helps ensure projects stay on track.

- Support Local Economy: Choosing local fabricators supports local businesses and contributes to the economy.

- Tailored Solutions: Local fabricators are often more inclined to offer personalized service, understanding community needs and industry standards.

Choosing the Right Steel Fabricators Near Me

The selection of a steel fabricator is a crucial decision that can greatly impact the success of your project. To make the right choice, one must consider various factors.

Key Considerations for Selection

When searching for the right steel fabricators near me, consider the following:

- Experience: Assess how long the fabricator has been in the industry and their track record on similar projects.

- Portfolio: Review past work to determine their expertise in specific types of fabrication.

- Certifications: Check if the fabricator has relevant accreditations that boost their credibility and expertise.

- Customer Feedback: Look for testimonials and reviews from previous clients to gauge satisfaction and reliability.

Evaluating Competency and Experience

Evaluation of a fabricator’s competency requires diligent research. Obtaining referrals from previous clients can be invaluable. Additionally, industry reputation through online reviews and trade organizations can affirm a fabricator’s reliability and competence in executing steel projects efficiently.

How to Compare Quotes Effectively

When seeking quotes from multiple fabricators, it’s essential to compare comprehensively. Look beyond just pricing:

- Services Included: Ensure you understand what services are included in the quote to avoid hidden costs.

- Delivery Timelines: Compare lead times and how they impact your project schedule.

- Material Quality: Inquire about the source and quality of steel being used, as cheaper does not always equate to better.

Types of Projects Handled by Steel Fabricators Near Me

Steel fabricators cater to a broad spectrum of projects, ranging from small residential needs to large-scale industrial applications.

Commercial Metal Works

Steel fabrication is integral to commercial building projects. Steel signs, frames, and support structures are common applications. Fabricators work closely with architects and contractors to ensure that materials meet both design specifications and safety regulations.

Residential Custom Fabrication

Homeowners and builders often seek custom metal work for enhancements such as railings, gates, and outdoor structures. The ability to create unique designs tailored to specific home aesthetics adds significant value to residential properties.

Industrial Applications

Steel fabricators deliver critical components for industrial operations, including machinery frames, scaffolding, and specialized equipment parts. These fabricators often have the expertise to handle high-volume production runs while maintaining quality standards that are crucial in heavy industries.

Innovation in Steel Fabrication

The steel fabrication industry is continuously evolving, driven by advancements in technology and methodologies that enhance efficiency and sustainability.

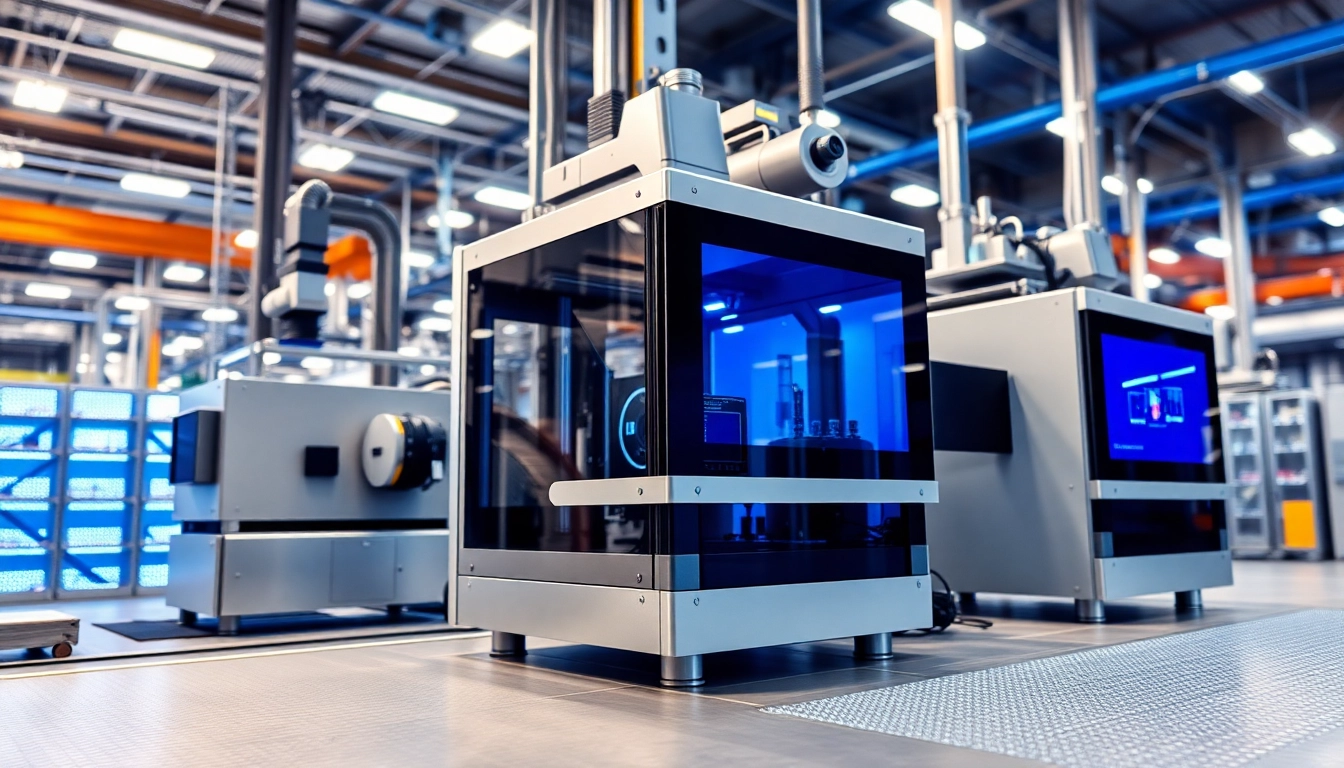

Latest Technologies and Techniques

The integration of Computer Numerical Control (CNC) technology has transformed the landscape of steel fabrication. CNC machines allow for precise cutting and shaping, significantly reducing waste and increasing productivity. Beyond CNC, the advent of 3D printing in metalworking is also gaining traction, enabling quicker prototyping and complex designs that were previously unfeasible.

Eco-Friendly Steel Fabrication Practices

As industries move towards sustainable practices, steel fabrication is also embracing eco-friendly techniques. Recycled steel utilization is growing, as well as the implementation of energy-efficient equipment and processes that reduce the carbon footprint of manufacturing activities.

Future Trends in the Industry

Looking ahead, trends such as the integration of Artificial Intelligence (AI) for optimization of design processes and predictive maintenance promise to revolutionize the industry. Moreover, the continuous exploration of sustainable materials and techniques will likely pave the way for a greener future in steel fabrication.

Maximizing Value from Steel Fabricators Near Me

To ensure that you receive the best value from your chosen steel fabricators, adopting a structured approach can be beneficial.

Best Practices for Working with Fabricators

Effective communication is fundamental. Clearly articulating project goals, specifications, and expectations helps establish a collaborative relationship. Additionally, staying engaged throughout the project can lead to better outcomes, such as avoiding costly misinterpretations.

Understanding Lead Times and Delivery

Understanding the lead times is essential for planning a successful project. Factors such as project complexity and the availability of materials can influence delivery times, so inquiring about these aspects during the initial discussions can set correct expectations.

Long-term Maintenance of Fabricated Products

Quality steel products require maintenance to ensure longevity. Establishing a maintenance plan that outlines regular inspections and necessary repairs can prevent minor issues from becoming significant problems, ensuring your investment remains sound for years to come.

Leave a Reply